Slot Power

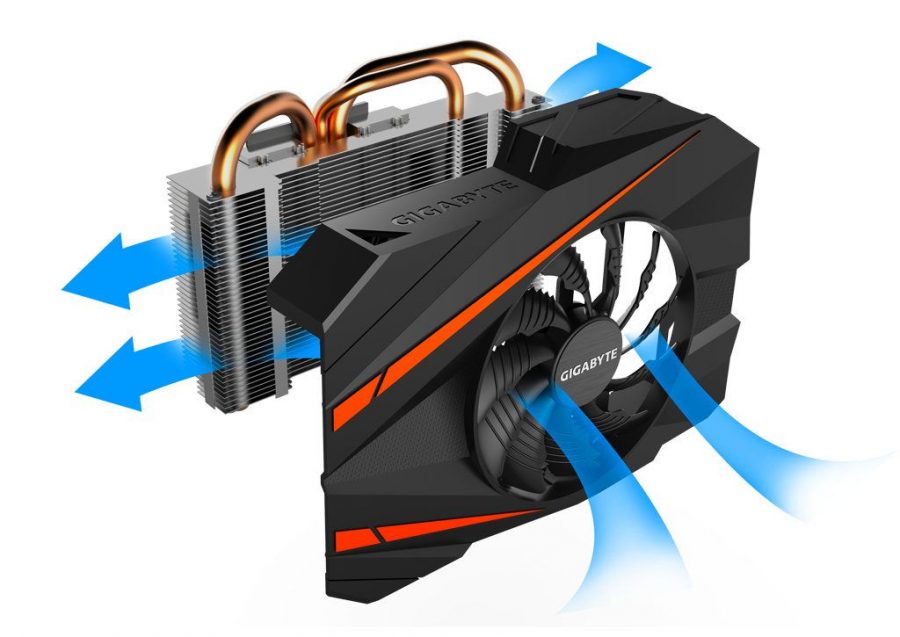

This is my pcie slot (dell inspiron 3250) what is my pcie slot?? 25w or 75W (its length is 8,8cm). I can't find information about it in dell website? I am planning to install a gtx 1050mini, of course i'll purchase a new psu for this card,but it requires a 75w pcie slot.THAT IS T. The increase in power from the slot breaks backward compatibility between PCI Express 2.1 cards and some older motherboards with 1.0/1.0a, but most motherboards with PCI Express 1.1 connectors are provided with a BIOS update by their manufacturers through utilities to support backward compatibility of cards with PCIe 2.1. HPE Common Slot Power Supplies share a common electrical and physical design that allows for hot-swap, tool-less installation into HPE server and storage solutions. These power supplies are available in multiple, high-efficiency input and output options, allowing you to 'right-size' a power supply for specific server/storage configurations.

- 200 Free Slots 4 U

- Slot Powers Casino Instant Play

- Vegas Power Slots

- Slot Powers No Deposit Bonus

- Slot Powerpoint

- Slot Power Limit

“Scotty, we’ve got to have more power – NOW!!”

How about those cute little Tomy AFX Controllers? Pity there not much good for adult hands. They have a limited life span and will fail after a point. So if you have worn out your controllers, you are faced with a choice. Now is a good time to purchase a better controller.

If you have a hobby shop with a HO raceway close by, see if they can order you a Parma 45 ohm Econo Controller. If not, go on-line or to eBay and look them up. They are a great first-step upgrade.

When you have it in your new unit, you can see it has three wires – not two like the set units. That third wire is for ‘dynamic braking’. Check the back of the Parma box for wiring instructions. ’Dynamic Braking’ gives you better car control with some car designs. It’s a nice feature to have for cars that tend to ‘roll’ a lot after you let off on the trigger.

Once you have better controllers you should invest in a better power supply. You are after a REGULATED power supply (one that is variable is good) that has plenty of amps. If your cars slow to a crawl on the far side of the track it may not be a car or track problem. The blame is more than likely the small amount of Milliamps being put out by the standard Tomy AFX power pack. A better power supply will fix that problem. It also means that you can use the ‘Dynamic Braking’ feature of the controllers much easier.

Modern AFX and Tyco slot car motors require a power supply producing 18 to 20 volts of direct current (VDC), while older Model Motoring cars require 20 to 24 VDC. The wall-outlet power pack supplied with most boxed racing sets is not sufficient for use on large table-mounted racing layouts.

DC power supplies normally have two specifications, the output voltage and the output current. Modern HO slot car motors require at least 18 VDC, and 1 ampere or more of current for proper operation. Most of the DC power supplies currently being manufactured provide only 12 to 13.8 VDC. These WILL NOT work for HO slot car tracks. They will however work properly for larger 1:32 and 1:24 scale slot car tracks.

A good quality DC power supply is essential to safe, trouble-free racing and prolonged motor life. Investing in a good power supply will quickly pay for itself in motor savings alone.

A good rule of thumb to use when determining the size of the power supply required is to multiply the number of lanes by 1 ampere or more. Especially long layouts or very hot motor armatures may require more power, but 1-2 amperes per lane should be sufficient for all but the most demanding racing situations.

A 5-10 ampere DC power supply would be a good choice for a long 4-lane racing layout. This should provide sufficient power with an adequate reserve.

Power needs to be applied evenly around the entire race track. Slot car tracks with lane lengths greater than about 20-25 feet will need to have power applied at several locations. The rail connections at the joints in plastic sectional track are the single largest factor contributing to voltage drops as the cars move farther and farther away from the power terminal track.

Modern AFX and Tyco slot car motors require a power supply producing 18 to 20 volts of direct current (VDC), while older Model Motoring cars require 20 to 24 VDC. The wall-outlet power pack supplied with most boxed racing sets is not sufficient for use on large table-mounted racing layouts.

It is often said that power should be applied every 15 or 20 feet for an even power distribution. This is true, but an even better way of determining power terminal track spacing is to count track joints. It is the joints that rob your track of power not just the length. Applying power every 12 to 15 track joints will assure that your track is properly powered.

It is important to determine where power will be applied before you build your track and mount it permanently to a table. Racers who skimp on adequate track power distribution will be disappointed when they have completed their track and find that cars slow dramatically on those sections of the race track farthest from the power taps.

Replacing the power supply with a unit producing higher amperage has very little effect on power distribution. Inadequate power distribution produces voltage drops around the circuit. All of the amps in the world can’t overcome this drop in voltage though.

Powering each lane with 1 or 2 amperes is sufficient if power is distributed evenly. It’s far more important to apply track power evenly around the racing circuit than it is to have a high-output power supply feeding a single set of power terminal tracks. Regardless of the power supply output, cars will slow down dramatically as they travel farther away from the power source.

Generally speaking, a 4-lane race track mounted on a 4×8 foot table would require 2 or3 power taps, while a 4×12 foot table would probably require at least 4 or 5 taps. Even larger and longer race tracks may need as many as 10 power taps. Count the joints for a single lane and then divide by 12 or 15 to get a better idea as to how many power taps your particular track design requires.

If you get a variable power supply wired in, varying the voltage output to the track directly affects speed. The standard generally accepted voltage level is 18 volts. The more volts, the faster you go, the faster you come off the track!!

Introduction: Digital Slot Car Power Distribution

Ever built yourself a large slot car layout and found that the cars just don't seem to have the same performance? Or do you hate it when your races are interrupted by the cars stopping because of bad joints? This Instructable will show you how to get your digital race track running faultless.

Please note that this is for digital track, which is where you can race with multiple cars in the same slot. If you wish to do this for systems which run one car per slot on analog controllers, there is a few notes at the end to help you modify it.

Supplies:

You will need the following tools -

- Soldering Iron

- Solder

- Cutters

- Strippers

- Screwdriver

- Ruler

You will also need the following components (Part numbers from www.DigiKey.co.uk )

- Matrix or Strip board (any will do) x1

- PCB standoffs (M3, any length or type will do) x4

- 3 pin PCB mounted header - WM2745-ND x5

- 3 pin connector housing - 900-0022013037-ND x5

- 22-30awg Crimp - WM1114-ND x10

- 2.5m Red Hook up Wire - 2200/26RD-100-ND

- 2.5m Black Hook up Wire - 2200/26BK-100-ND

- Epoxy Glue (Any will do)

Step 1: Building the Board

The construction of the board is simple. Solder the 5 headers in place, then if using matrix board, solder the board to create tracks linking the outside pins in parallel lines. In strip board, ensure that the strips will connect the outside pins of the headers. If you have a multimeter, it pays to check to ensure that all of the number 1 pins are joined, and all of the number 3 pins are connected. There shouldn't be and connections made between any number 1 and 3 pins or it can damage your power base.

This gives you 5 connection points, if you wish you could add more. The next step explains how and why this works!

If you don't know how to solder then please check out this Instructable https://www.instructables.com/id/How-to-solder/ (Thanks Noah!)

Step 2: The Science

Without diving too much into details of how resistances work, I will give you a simple explanation so you know why and how this works. If you want a more detailed explanation then please do look up Ohm's law and Kirchoff's law.

Fig.1 shows a circuit representation of a slot car track. Each of the resistors represents a joint in the track. No matter how good the connection, there will always be a small resistance here, which hinders the flow of electrons (electricity). Every resistance causes the voltage to be a little bit lower, so when the car is further away from the power base, it has less voltage to power it. This leads to poor performance from the cars, and when multiple cars are on the track this effect is even greater, possibly even stopping the cars.

If there are then two breaks in the track, this section between the breaks will become a dead zone and nothing will run at all. It would seem to any logical person that what is needed is more power bases.

Fig.2 shows a circuit with our power distribution system fitted. Now we can see that we have far fewer resistances in between each power 'tap'. This means less volt drop so our cars get more voltage, and that means more performance. Multiple cars racing will then be able to run better so your races will run smoother with less track issues. Any breaks in the track are also far less noticeable as instead of two breaks over the whole track, there must be two breaks in each section to have an effect.

200 Free Slots 4 U

Step 3: Preparing the Wires

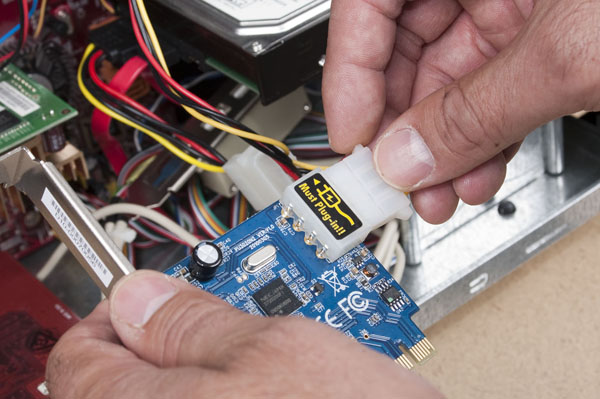

Now its time to get the interconnecting wires prepared. First, cut a red and black wire of about 10cm for each piece of track we are going to 'tap'. These will need to have 5mm of insulation stripped away so you can twist and tin them using a soldering iron. There is an image showing me tinning a wire above.

Next cut a red and black wire for each tap. I would suggest 2 meters but if you have a bigger track than 4 meters then you may need them longer. Once cut, it makes a tidier job if you twist these together. I did this by holding one end in a clamp, and clamping the other in the chuck of a battery drill. I then pull it tight and operated the drill until I had twists of about 1-1.5 per cm. Be careful when you release an end as it may try to unravel a bit which could cause injury. Also beware that the overall length will reduce when twisted together so take this into consideration when cutting. As with the short tails, strip by 5mm and tin the ends.

SAFETY FIRST! :- Always ensure an adult is present when using tools. Soldering irons are hot, very hot, so please be careful. Power tools can be dangerous especially when using them in ways which the weren't intended to be used!

Step 4: Jumper Wires

On your selected track pieces (I have used 4 half length pieces), turn them upside down and as shown in the second picture, tin a couple of metal tabs. Then tin tabs on the opposite lane at the same location ready to add our jumper wires.

When this is done, solder one end of the red jumper to the outside rail of the outside track, then black jumper to the inside rail of the outside track. Then you can solder the other end of the red jumper to the outside rail of the inside track, and black from the inside rail of the inside track.

We must ensure that we maintain the correct polarity to ensure that we don't create a short circuit. I chose 4 pieces of identical track, so that it is easy to see that each has been done identically to reduce the possibility of mistakes. If you want to pause after this step, a quick way of checking your work is to check with a multimeter that you have continuity. The fifth picture shows coloured lines on the track to show which ones should be connected when testing.

Step 5: Attach the Twisted Tails

Next pick which side you wish to add your twisted tails to and solder them on to match the jumper colours you fitted earlier.

Top Tip: If you are struggling to hold the tail and solder it in place, it helps if you hold it with the tip of a small flat screwdriver.

Again it is important to make sure that you make all of your pieces identical so that when it comes to building the track, there is minimal risk of creating a short.

Step 6: Connecting to the Power Base

If you don't feel confident enough to hack your power base, then you don't need to, just ensure one of your taps is next to it when you build your track. But if you feel confident enough then the results are worth it. Please be aware that this could invalidate your warranty and if done improperly could damage your power base.

First remove the screws holding it together and carefully separate the track from the base. Do not cut or break any wires, and find a free pair of metal tabs on one lane. Next tin them as before, and connect the tails ensuring that you are matching the colours you have done on your other tails. Ignore the wire colours in the power base as you may have chosen opposite colours! You could always open up your power base first and make all the colours match if you so wish.

Step 7: Fitting the Plug Housings

Next you need to fit the crimps onto the tails. I used a pair of cutters to do this as I don't have the correct crimping tool. It is ok to do this but be careful not to accidentally cut through the crimp. I also added a little solder once I did this to ensure a good connection.

The housings all have tabs, which helps you to orient them the right way round. It matters not which way you have it so long as they all match (Can you see a theme going here!).

Slot Powers Casino Instant Play

Step 8: Make Your Work Last

as you can see in the image above, all of my pieces are identical. This ensures that there wont be any short circuit when they are connected. But as the wires are easily snagged and pulled, it helps to make a better job if you mix up some epoxy glue, and apply it to fix the wires to the track. Don't put glue on the soldered parts, as it could drip onto the track and cause running issues for the cars. Instead I put a blob in the middle of the jumpers, and a blob on the twisted pair before they leave the track.

Ensure you use the epoxy glue as directed, and kids, always use adhesives under the supervision of an adult!

Vegas Power Slots

Step 9: Using Your New System

As all of our pieces are identical, we can ensure that we have no short circuits by orienting all of the modified pieces so the wires all face inwards. Then hook up all the wires to the board, ensuring all the plugs are the right way round. Then switch on your system, pop your cars on the track and away you go!

Please note that this only works in this format on Digital tracks, as cars can race on both lanes, change lanes or run in opposite directions. That's not to say that it cant be modified for 'normal' track. All you need to do is not fit the jumpers and build two boards, one for the inside lane and one for the outside lane. This is a little more tricky to get the polarity correct though so only attempt this if you are confident.

This modification is based on the slot cars and system that I have, and it may not work with others so please do check what you are doing with other makes.

Please do comment with any problems or questions you have and I will try to answer them all. If you don't have a question, then feel free to post details of your versions and pictures of your layouts.

And finally, On your marks, get set.....GO!!!

Be the First to Share

Slot Powers No Deposit Bonus

Recommendations

Slot Powerpoint

Slot Power Limit

Microcontroller Contest

Automation Contest

Make it Glow Contest